Fishing is great year round in Louisiana. But with the onslaught of cold fronts characteristic of late winter and spring, no time is better to pay due to your boat trailer.

I would literally drive my boat trailer into the ground before I'd take time to perform maintenance on it. I'd service the poor thing only after the bearings have exploded and wheels flown off the axle.

I have owned aluminum and steel trailers, and they all need attention. In fact, it seems everything else gets attention before the trailer does.

One of the best times of the year to do that is during the late winter and early spring, when the onslaught of cold fronts makes it inconvenient to fish our inshore waters.

Why should I service my boat trailer?

The answer is obvious, but I want you to stop to actually think about it.

Avoid Accidents

Years ago I had a wheel literally fly off the trailer going down the highway.

A year of dunking the trailer twice a day, ten to fifteen days a month had taken it's toll: the bearings exploded, the axle nut sheared in half and bye-bye went the wheel, bouncing through median and across lanes to the far side of the highway.

Luckily nobody was on the road, or they would have eaten a rogue wheel with their windshield.

Stop Taking Shortcuts

Rushing from fishing trip to trip, taking shortcuts on maintenance, putting a "band aid" on things (read: bailing wire, duct tape, zip ties) is asking for a catastrophic break down to happen.

Maximize Good Fishing Time

The best reason to maintenance your trailer during your off time is that you don't worry about it during your "on" time. Time on the side of the road fixing a breakdown falls into my least favorite time category: not fishing.

This is especially the case when off time is better spent in the garage at home when northwest winds are blowing over 20 knots.

Everything on my boat trailer is beefed up so it is tough, corrosion resistant and ready to launch the boat. Worrying if the trailer will survive the ride home is not having peace of mind.

It's that peace you seek on your fishing trips, isn't it?

What are some things you should look at?

This is not an in-depth and detailed "how to" for each serviceable item on a trailer.

Rather, it's a quick guide to help you spot common issues before they turn into serious problems. You don't have to be mechanically inclined to see if something needs replacing on a boat trailer.

Here are a few places you can begin:

Hub Assemblies

Jack the trailer wheel up off the ground. Spin it with your hands and check these things:

- Does it spin freely?

- Are there any grinding noises?

- Does the wheel wobble or spin straight?

If so, something is amiss and your bearings need to be replaced. Don't live in denial about it.

Gambling on the bearings magically healing themselves and surviving the entire summer and fall is living in a make-believe world.

Roll your sleeves up, pull them off and get new ones. Replacing bearings is easy.

Lug Nuts

Are the lug nuts and lugs on your hub corrosion free? Can they be easily removed?

I have had lugs and lug nuts corroded so badly that an impact wrench couldn't get them off.

They were cut off before installing new ones. If it's not obvious to you, having lug nuts that easily separate from their lugs is key to changing a flat tire in a timely manner.

Few things are more nerve-wracking than fussing with fused lug nuts while sitting exposed on the side of the interstate.

Trailer Lights

Start from the connector in front of the trailer and work your way back, checking wires. Any wire that has insulation rubbed or pinched off needs to be replaced. Corrosion is a dead giveaway.

Any kind of connection between two wires should not be below the water line on the trailer, or the part of the trailer that will be underwater while launching the boat.

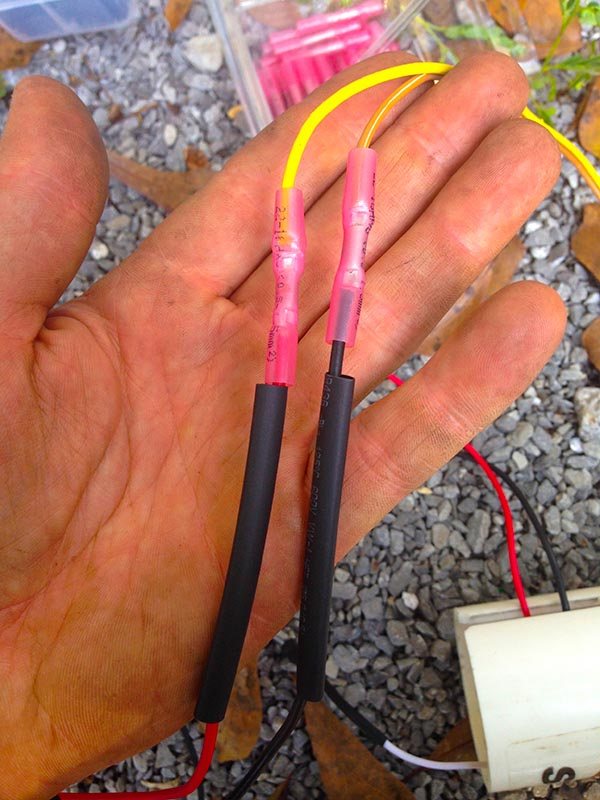

On my trailer, all wires are connected with marine grade butt connectors and a layer of heat shrink on top of that.

Most trailer manufacturers use the trailer as ground, so look where those points are. If your lights are dead then don't be surprised to see the ground terminal corroded or completely broken.

Trailer Bunks

Have you seen a bunk floating away as you pull the trailer out the water? Yep. That's happened to me.

Keep an eye on your trailer bunks. The best time to get a look at them is right after launching the boat and parking the truck.

If they look like they are about to fall apart then think about getting new ones.

It's not rocket science. It's a piece of wood and four bolts.

Two is One and One is None

This old axiom merely underscores the need for having a backup when the original fails.

This doesn't mean you need multiple spare tires, it means you should check the spare you have to ensure it is in good working condition.

Op Check Your Gear

When your trailer inevitably breaks down, do you have the appropriate tools to get it fixed in a timely manner?

Quick Story

A friend of mine had a flat tire the other day. What seemed to be an easy five-minute fix turned into an all day event.

Yes, he had tools to change out the tires, but they were not the right sized tools. Then it turned out the spare tire fit a different truck and not his.

This guy was a total soup sandwich and a little foresight would have prevented that.

You don't need professional grade tools to change out a tire like in NASCAR, but having the right ones is key and shows the world you know what you are doing.

Great input, thanks for sharing!

Good advice, thanks for sharing!

use “never seize” on wheel studs to prevent freeze up and galling of lug nuts

Liquid tape on top of the heat shrink and covering the grounding points on the trailer goes a long way in corrosion prevention as well.